在桥梁建设项目中组装和拆除钢模板时有哪些注意事项

9 月 25, 2024

桥梁钢模板变形的原因是什么?处理桥梁钢模板变形的方法有哪些?

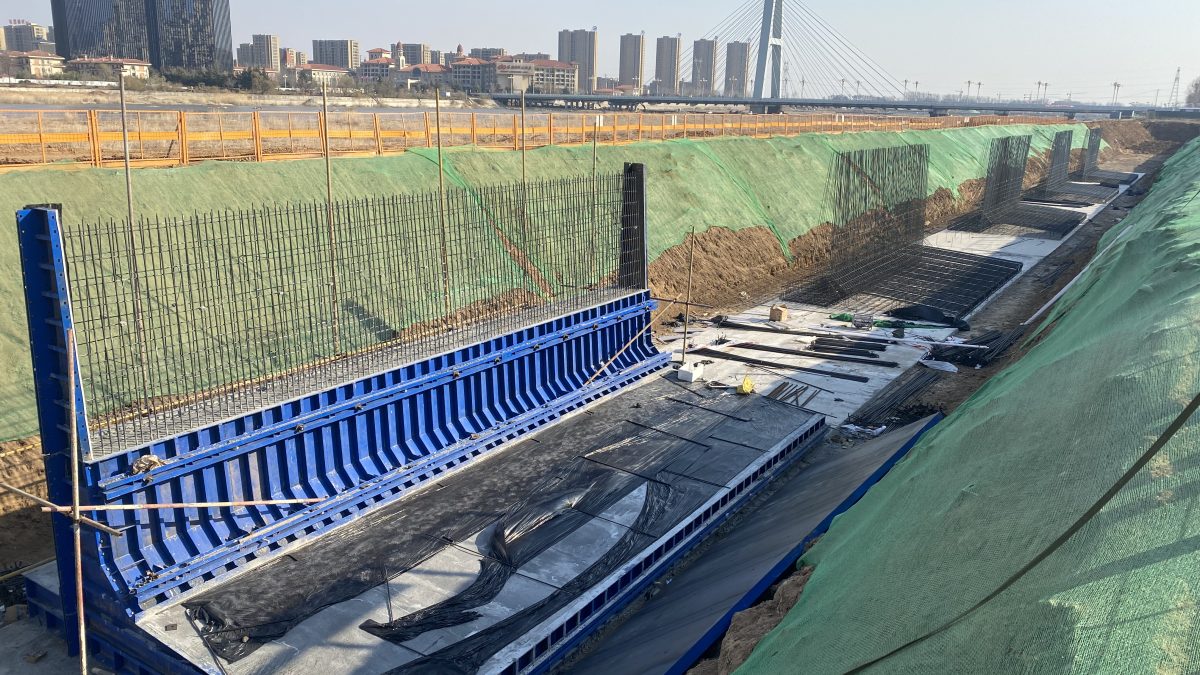

9 月 25, 2024In the construction of bridge engineering, before pouring the concrete, the internal structure of the steel formwork should be checked for dirt. If there is any, it should be dealt with in a timely manner to ensure that the surface of the formwork is clean. Furthermore, whether there are gaps, holes, etc. at the joints of the 钢模板 should be immediately blocked to avoid grout leakage after pouring.

- 1.When assembling the steel formwork, the assembly should be carried out according to the design points.

- 2.It is best to use large steel formwork as the main guide plate to reduce assembly time. This not only saves assembly time, but also comprehensively improves the overall compressive strength of the steel formwork system software, which is conducive to disassembly and assembly.

- 3.The installation of steel formwork should be arranged in a bottom-up order, with each formwork positioned correctly and strictly carried out in accordance with the engineering drawings. The surface of the template should be leveled and tidy, and the connectors must be tightened to maintain a tight joint.

- 4.Cylindrical steel formwork is prone to column distortion and displacement during installation, resulting in serious errors in beam connections, which seriously affects the overall quality of the project. Avoidance measures: In the actual operation of template support, the steel reinforcement parts of the building should be corrected according to the design points and then fixed in place; Corner molds also need to be set up at the corners to ensure proper angles. The specifications, models, and specifications of the hoop are strictly designed and manufactured according to the design drawings, and the tightening work is also done well.

- 5.During the installation of wall mounted steel formwork, it is easy to encounter various problems such as uneven thickness, insufficient vertical angle, large upper opening, and rotten feet. To avoid these issues, it is important to use anchor bolts and standard components for the connection of the steel formwork; The specifications of bolts passing through walls must be strictly carried out in accordance with the design points; The upper opening of the wall must have a tightening measure.

- 6.The assembly of beams often encounters many problems such as uneven height, uneven bottom end, raised side edges, and large upper openings. Avoidance method: The specifications, specifications, and spacing of the transverse and longitudinal steel ribs of the beam steel formwork must be strictly obtained according to the calculation; The support system needs to have the rigidity and strength of renting and purchasing to avoid deformation after carrying out cast-in-place concrete; The upper end of the beam should be pulled with a tightly closed mouth rod; The support system of the steel formwork must be installed on a solid ground to avoid deformation caused by downward movement during casting.

结束

在 Facebook 上

推特

LinkedIn

X

WhatsApp

相关帖子

5 月 26, 2025

4 月 5, 2025