What are the precautions before pouring concrete using steel formwork?

25. September 2024

Kennen Sie den Herstellungsprozess von Stahlschalungen?

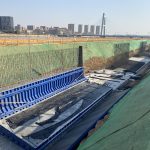

25. September 2024Steel formwork is a commonly used item in bridge construction projects, mainly used for concrete pouring and forming. In addition to steel formwork, there are also other materials such as wooden formwork and plastic formwork. However, from the perspective of construction quality and high efficiency, the application of steel formwork is more extensive. Steel formwork for highway bridges is widely used in bridge construction due to its characteristics of long capital turnover time, beautiful and generous casting shape, and good construction quality.

In the use of steel formwork, it is common to cause deformation due to incorrect operation or negligence. What is the reason for such situations? How should we handle it? Below, Bosheng Steel Template brings you many reasonable ways to handle it.

1、 The main reasons for deformation of steel formwork in highway bridges

The deformation caused by the steel formwork of highway bridges will affect the actual construction effect, and various inconveniences will occur in the subsequent construction process. If it is serious, it may even need to be rebuilt, greatly affecting the project progress and increasing the project cost.

The foundation of the steel formwork placement area for highway bridges is not strong enough, resulting in foundation subsidence.

- The installation and assembly of steel formwork are not carried out according to the design requirements, making it difficult to ensure comprehensiveness.

When using wooden templates or plastic molds, if the pouring work is not carried out in a timely manner after assembly, the highway bridge templates will be exposed to the air for a long time, causing deformation through precipitation and sunlight impact.

- 2、 How to avoid deformation caused by steel formwork

When carrying out the process of pouring and compacting concrete, the pouring should be carried out evenly, and the pouring height should be strictly controlled, especially on both sides of some highway bridges with holes. When ensuring the compactness of the concrete, it is also necessary to prevent excessive vibration force from causing deformation of the formwork.

When designing the steel formwork for highway bridges, it is necessary to ensure that the formwork project has the load-bearing capacity and reliability for rental and purchase. The weight of the formwork itself, the load generated during the construction process, and the lateral working pressure generated during the concrete pouring process should be considered.

If wooden or plastic formwork is used, pouring work should be carried out promptly after assembly to prevent deformation caused by long-term exposure of the formwork to the air.