اتصل بنا

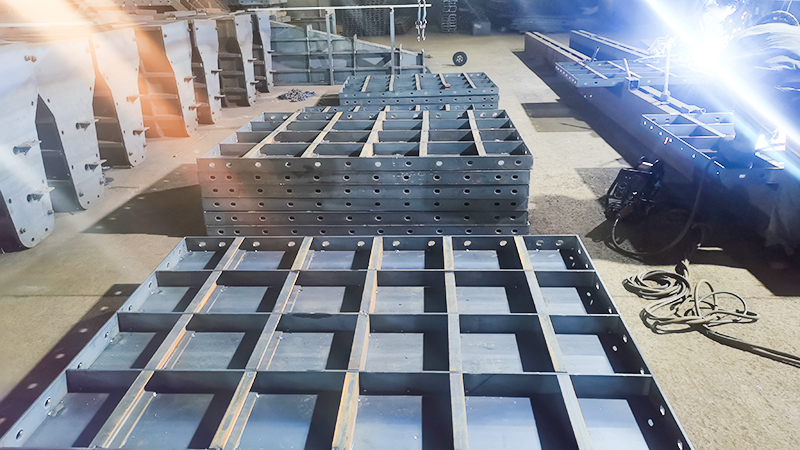

اتصل بخبراء بانسول الفنيين لمساعدتك في اختيار القوالب الفولاذية ومنتجات الدعم المناسبة لمشروعك.

TEL

+8615194153351 +8615275190139

البريد الإلكتروني

pansol@pansolform.com

لينكد إن

صب الخرسانة بانسول

إضافة المصنع

رقم 6 طريق بييوان، مقاطعة بينغيوان، مدينة ديزهو، مقاطعة شاندونغ، الصين